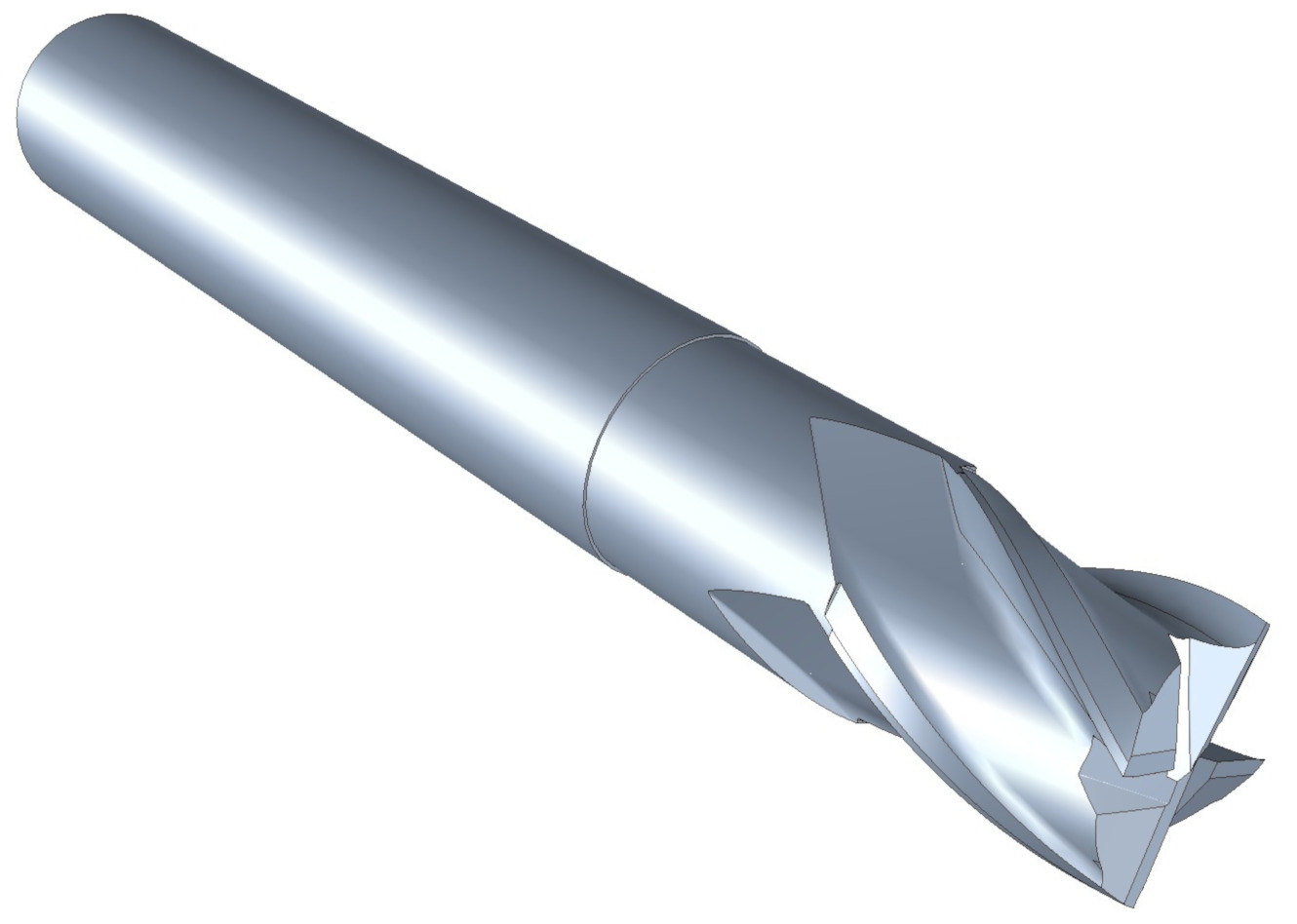

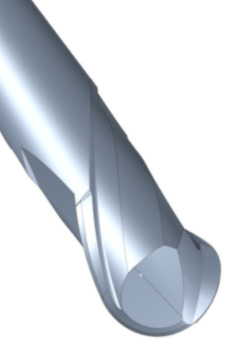

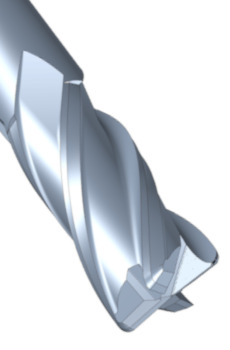

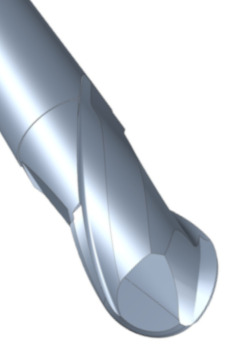

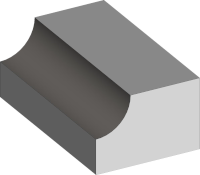

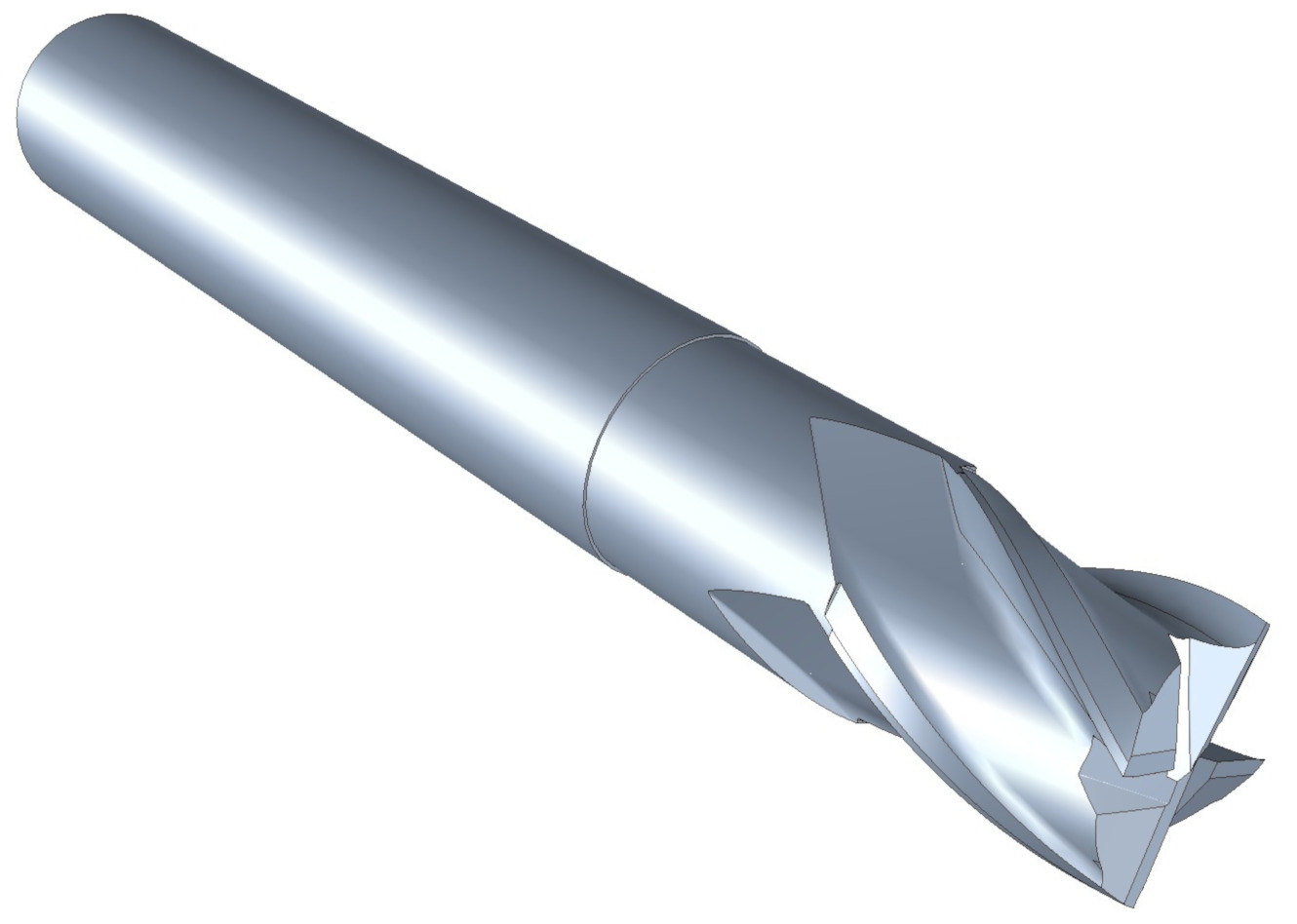

Description

The cutters have been designed for a wide range of materials and machining strategies for various industries. Advanced geometry allows the use of tools in both roughing and finishing, also using high-volume strategies like Volumill or Vortex.

| Machining type | Type of cooling | Type of processing | ||

|---|---|---|---|---|

|

MQL AIR AIR |

F | SF | R |

| 3 | 2 | 1 | ||

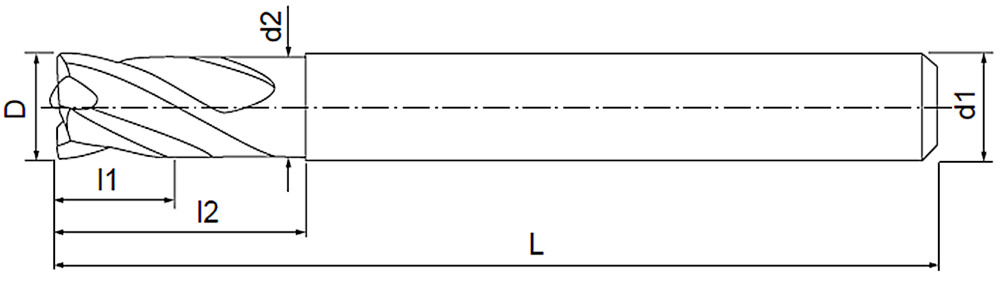

Dimensions

| UT tool index | D | d1 | d2 | L | l1 | l2 | z |

|---|---|---|---|---|---|---|---|

| UT.4100.0400 | 4 | 6 | 3.8 | 55 | 6 | 10 | 4 |

| UT.4100.0500 | 5 | 6 | 4.8 | 55 | 7 | 13 | 4 |

| UT.4100.0600 | 6 | 6 | 5.8 | 55 | 8 | 15 | 4 |

| UT.4100.0800 | 8 | 8 | 7.7 | 65 | 10 | 20 | 4 |

| UT.4100.1000 | 10 | 10 | 9.7 | 82 | 12 | 25 | 4 |

| UT.4100.1200 | 12 | 12 | 11.7 | 82 | 14 | 28 | 4 |

| UT.4100.1600 | 16 | 16 | 15.7 | 110 | 8 | 32 | 4 |

Parameters

| Material group |  |

|||||

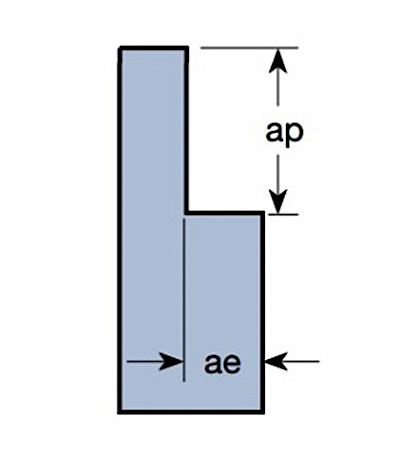

| ap ≤ 0.5D | ae ≤ 0.02D | ap ≤ 0.1D | ae ≤ 0.03D | ap ≤ 0.02D | ae ≤ 0.75D | |

| vc | fz/D | vc | fz/D | vc | fz/D | |

| P1 | 180-200 | 0.0055 | 210-230 | 0.0060 | 160-180 | 0.0045 |

| P2 | 180-200 | 0.0055 | 210-230 | 0.0060 | 160-180 | 0..0045 |

| P3 | 150-165 | 0.0045 | 160-180 | 0.0050 | 140-155 | 0.0035 |

| P4 | 110-130 | 0.0035 | 120-135 | 0.0040 | 90-120 | 0.0030 |

| P5 | 125-145 | 0.0050 | 150-165 | 0.0050 | 120-140 | 0.0040 |

| P6 | 100-120 | 0.0035 | 115-125 | 0.0040 | 75-95 | 0.0030 |

| H1 | 115-125 | 0.0045 | 125-135 | 0.0050 | 100-115 | 0.0040 |

| H2 | 90-105 | 0.0035 | 100-115 | 0.0040 | 80-95 | 0.0030 |

| H3 | 60-80 | 0.0025 | 70-90 | 0.0030 | 55-70 | 0.0020 |